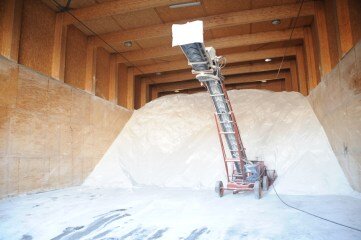

“Good luck” (the German miners’ greeting) echoes through the halls of the Schönfeld Road Maintenance Depot in the Ore Mountains early in the morning. The thermometer reads -21 °C as the first few sun rays appear above Saxony’s highest mountain, the Fichtelberg. About 30 staff members at the Schönfeld Road Maintenance Depot take care of the roads – in both summer and winter. As soon as the first snow falls, things get particularly turbulent for the road surveyors. Then it’s time to harness the ploughs and load de-icing salt. The new salt storage facility can accommodate up to 2,200 tonnes of salt; smaller amounts are stored at other external facilities in Markersbach and Oberwiesenthal in order to minimise the travelling times for refilling salt during the shift. Sodium lye is additionally filled in to reduce the consumption of salt and ensure that the roads quickly become dry again. 255 kilometres of road need to be cleared of snow and ice – at altitudes of 400 to 1,200 metres. The winter service vehicles are also employed on top of the Fichtelberg. Unlike many winter sports regions, an access road leads from Oberwiesenthal, the highest town in Germany, to the top of the Fichtelberg, where a great number of parking spaces are available for visitors and winter sports fans. The traffic volume is extremely high, particularly at the weekends, keeping the 25 road surveyors very busy.

“The work of road surveyors in winter requires a high level of flexibility and precision, especially on our narrow but busy roads”, road surveyor Stev Landrock explains. “Once the white flakes have begun to fall, literally no day is like the other. Based on the weather forecast, we decide every day around 12.00 noon which vehicles and which drivers will be on duty the next day. Of course, this also applies to weekends and public holidays. If the weather forecast predicts snow or black ice, we work in three shifts.

In addition to a Schmidt Supra 4001 snow cutter blower, our vehicle fleet also includes a Unimog U400, to which either a Schmidt Vector S30 snow plough or a VF3 snow cutter can be attached, as well as a Stratos spreader. Our Schmidt VF 3-ZLB snow cutter, which we have properly overhauled, will also be used again with the Unimog. Moreover, a Unimog U1650 with a Schmidt FS4 snow cutter had been in use on the Fichtelberg for almost 20 years and has just recently been given to another road maintenance depot in the district.”

The daily work of Stev Landrock and his colleagues in winter often involves extreme weather conditions. Not only do they have to overcome a level difference of 800 metres every day, but they also have to deal with regular extreme ice formation and snow breakage due to the geographical location. “Mild and humid air rising up from Bohemia to our higher and colder elevations causes extreme ice formation on trees, traffic signs and ultimately also on the roads.” That makes absolute reliability of the vehicles and technical equipment in any situation all the more important to the experienced road surveyor.

“The durability and reliability of the equipment is remarkable”, Stev Landrock says. “Our latest Schmidt snow plough is from 1997, which means it has been in use for almost 20 years, and the oldest one has been in service for as many as 24 years. During one good winter season alone, a snow plough works up to 475 hours of operation. By contrast, the maintenance requirement is very low and the performance is still perfect after all these years. The Schmidt Vector snow plough equipped with multiple spring flaps is particularly appreciated for the especially aggressive clearing of large amounts of snow on icy ground, resulting in a neat clearing pattern and relatively low salt consumption. Since many of our roads have traffic barriers, the high snow ejection level of the Vector S30, which minimises the formation of snow banks, is also beneficial. We are particularly proud of our Supra 4001, which has been part of our vehicle fleet since 2012. It helps us remove the sometimes tremendous amounts of snow in the Fichtelberg region quickly and efficiently. The articulated steering makes it easy to manoeuvre and the telescopic driver’s cab offers an excellent all-round view, especially while loading snow. Another great advantage is offered by the cutting drums that are open to the outside, preventing the vehicle from being “pushed aside” while cornering.”

Manoeuvring on the narrow and sometimes quite steep roads while always keeping an eye on the plough and spreader requires full concentration at all times. Martin Weißflog, one of the 25 road surveyors, has nevertheless found his dream job. His working area also includes the Fichtelberg. He loves the variety and appreciates the responsibility associated with his work. And even though his working day often starts when all others are still sleeping – the view from the Fichtelberg at the end of the shift rewards him for his efforts every day.